Incoming Inspection

For every part of the machine, G.weike will strictly control the quality.

Not only require suppliers to provide quality inspection reports,

but also strict quality monitoring will be carried out when the parts are in the factory.

-

Laser Source Test

The width, repetition frequency and peak power of the laser pulse are detected by

using the photoelectric detectors and oscilloscope.

-

Laser Head Test

Stability test and aging test for laser head.

-

Square Track Detection

Testing the flatness and straightness of the

track to ensure that the machine runs smoothly.

-

Rack Detection

The precision and consistency between gear and rack are mainly tested

-

Motor / Reducer

Performance Testing

we will adjust the suitability of the machine through

continuous empty experiments.

Process Control

The assembly process of the machine will also affect the customer's feeling when using

the machine, Therefore, in the process of machine assembly, G.weke from the most basic

machine bed to the final assembly of the whole machine is strictly followed by the

quality management standard.

-

Machine Bed Welding

The bed frame is welding by 10mm thick and high strength square.

-

Gantry Milling

G.WEIKE has its own gantry milling.

-

Guide Rack Mounting

The straightness of guide rack is guaranteed by using laser collimator

-

Other Hardware Parts

Installation

we install the motor reducer strictly according to standard production

process and standard

pre-delivery Inspection

The machine will accept a number of quality testing, respectively, from the performance,

stability, fit, practical and other aspects of consideration, for non-compliance with

the standard part of the arrangements for debugging and maintenance , To ensure that

the final factory, the machine is in the best condition.

-

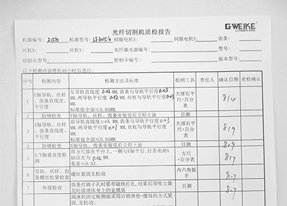

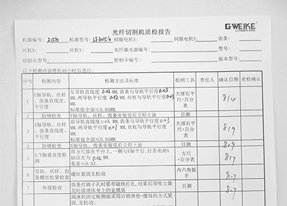

Inspection Report

Every component of the machine, every performance,

every parameter is carefully tested.

-

The Whole Machine Is Fitted

With a Load-Free Test

Ensure the cutting accuracy through laser interferometer checking and 24 hours testing,

And make sure the machine will be in the best condition.

-

Material Shearing Test

Before delivery, different metal materials will be cut, observe the cutting effect,

and then adjustment according to the need

-

Machine packing

The laser equipment requires multiple protective measures during the packing process to ensure

that each component is not affected by the collision

LASER QUALITY MANAGEMENT SYSTEM

LASER QUALITY MANAGEMENT SYSTEM